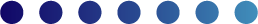

When a customer can’t find what they came to buy at your store, the impact can ripple in far-reaching ways, beyond a single instance of a lost sale.

The “cost” of not having the item available at the shelf can impact both retailers and manufacturers:

- Retailers risk losing the shoppers, if the customer encounters the issue and perceives a recurring theme that the store “never has what I’m looking for." In these cases, shoppers may elect to permanently switch stores due to OOS situations.

- Retailers risk additional lost sales if the consumers buy the OOS item at another store, cancel their purchases entirely or substitute a smaller and/or lower priced item.

- Manufacturers run a risk of losing customers if the item is unavailable and they switch to a competitor’s brand in the same category, where the trial leads to the shopper adopting the other brand -- not just for that immediate purchase, but for future trips, too.

- Manufacturers can risk loss of future sales/brand share whenever shoppers have occasion to substitute a competitor’s item or cancel a purchase.

In all of these cases, out-of-stocks can create a ripple effect, impacting more than just the retailer and customer. When the retailer loses the sale, they also risk losing the customer, the supplier risks losing brand loyalty to a competitor, and so on... By losing customers, this discrepancy can create inefficiencies in the supply-chain.

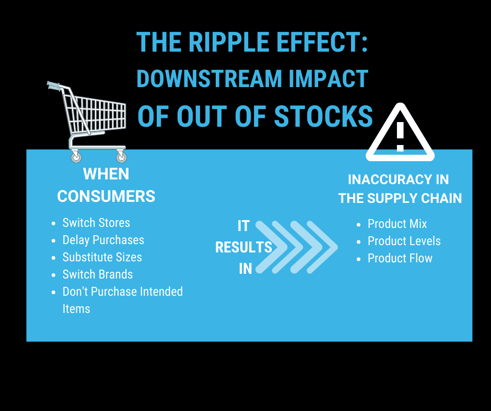

Estimating the Impact of OOS on Lost Sales

To really tackle improving on-shelf availability, you'll need to do a bit of research to better understand the causes of your out-of-stocks. Look to the following areas, typically responsible for impacting on-shelf availability:

- Item count discrepancies (whether through scanning/technology or human error, loss of goods due to damage or theft - or a combination)

- Forecasting or reporting inaccuracies

- Delivery or logistics problems

To calculate your OOS costs, you can use a formula like this one as a starting point. You'll need to know the out-of-stock rate for the category you're looking into. Next, it will help to understand how customers respond to out of stock instances for this category. Do they switch brands? Do they just not purchase at all? Lastly, you'll need to figure the total sales figure for the category.

Remember: depending on the product, category and competition, the worst case consequence of missing a sale results in customers trying a competitor, wherein, you risk losing them forever.

Identifying these gaps is a great place to start in your efforts to manage and improve your on-shelf assortment so you can maintain a lower out-of-stock rate.